We take a broad look at the current status of e-bike parts and components used to construct most e-bikes.

Within this broad survey we’ll take a deep dive into the main component classifications to see where things are, and based on that, where things may be headed.

The technology is rapidly evolving:

- batteries are getting bigger

- there are more of them on e-bikes

- there are more powerful and efficient motors

- IoT is becoming more important

to name a few of the main changes.

These are the key categories; the contents of each category are what will change. So we’ll update this article every year after Taipei Cycle and Eurobike since these events coincide with the release of a wide range of new e-bike components.

With brands fiercely innovating to win market share, each of these trade shows sees the introduction of many new models—some to fade away, never to be seen again; others, though, will come to dominate their niche.

Contents

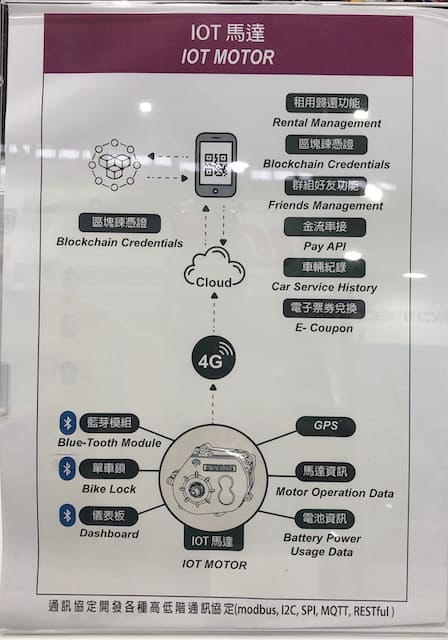

IoT

Let’s begin this coverage with what is the most promising domain of e-bike development: the integration of e-bikes—and particularly e-bike parts and components—into the Internet of Things.

In September 2022 the Bicycle IoT Techniques International Expert Symposium was held in Taichung.

The event was organized as a way to introduce legacy bike component companies to the rapidly developing electronics ecosystem in the bike industry.

Most of these companies were completely clueless. And given the pace of change, any company or bike geek for that matter, not watching closely will be left behind . . . and possibly be out of business sooner than later because of it.

The Micro-Mobility Revolution

Out of the several speakers that day, Dr. Mo-Hua Yang of the ExtraEnergy Consulting company was the most interesting.

Dr. Yang’s vision of the future is one dominated by he integration of IoT and micro mobility systems and applications, or what he calls the “micro e-mobility revolution”.

Other commentators and experts have all pointed to the centrality of “micro-mobility” in the form of electric vehicles in future transportation systems and networks.

But none really highlight how important IoT-connected e-bike parts and components will be in the future.

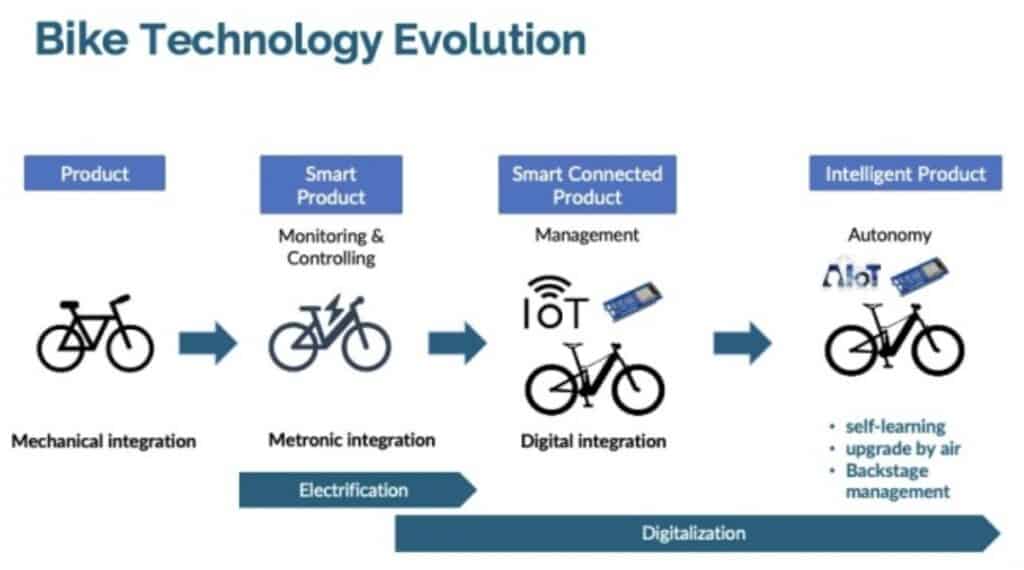

Dr. Yang has mapped out the past and future of e-bike development in his depiction of the evolution of bike technology.

It’s a clear ‘before’ and ‘after’—the history of bike technology belonged to the time when a bike was just a product . . . a steed built from a variety of components.

We’ve entered the ‘after’ quite suddenly.

Even though e-bikes have been around for decades, they reached a tipping point and really took off in the middle of the 2010s and we haven’t looked back.

Dr. Yang posits “Smart Product”, “Smart Connected Product”, and “Intelligent Product” as key stages on an evolutionary path.

While there is truth in this evolutionary trajectory, with the future a bit further out probably clearly belonging to intelligent products, the reality is that all three categories of products are available today.

The products in these categories can be seen to be intersecting in a number of complex combinations.

Some brands focus on smart products where others are hurrying to be identified as producers of smart connected products.

Let’s look at the degree to which these themes are reflected in the following product categories.

The three key elements that make an e-bike what is it are the motor, the drive train, and the battery.

We’ll take a look at each in turn taking special note of chains as an overlooked part of the e-bike package—conventional chains are not generally up to the demands that increasingly powerful e-bikes make on them.

Motors

Possibly the most competitive space in the supply of e-bike parts is e-bike motors.

With every edition of the Taipei Cycle and Eurobike trade shows the number of brands appearing in the market is increasing.

Key trends and characteristics of this sector include the following:

- Companies long active in the electric motor space in other industries are now moving into the e-bike business

- Big electronic companies are becoming established in e-bike part design and manufacture

- Geared motors aimed at eliminating rear derailleurs are becoming more common

Electric Motor Companies

Atech Totalsolution Co.has been around since 1973 and has honed their expertise in motor, battery, and control system integration, including IoT connectivity.

Their approach in which the integration of e-bike parts and components into an (ideally) seamless whole represents a key direction for the industry as a whole. Although HMI is implied here it probably should be at the center rather than the motor.

A systems approach is completely logical given the technology involved. Yet the experience of the Humans interacting with it will make or break the product.

CT Green Tech are another new entrant into the space and have also been around for a while. Their specialty is hub drives and have a variable 3-speed gear system built into a recent model (more on geared systems below).

Valeo is another one but we’ll look at them in relation to geared motors below.

Big Electronics

By “big electronics” we mean electronics companies that have been around for decades, in most cases. These companies have jumped into e-bike part making with gusto.

For one they have the capital to support various e-bike projects and not worry too much if the investment does not work out.

R&D is crucial and these companies typically plow a large percentage of revenue into R&D activities.

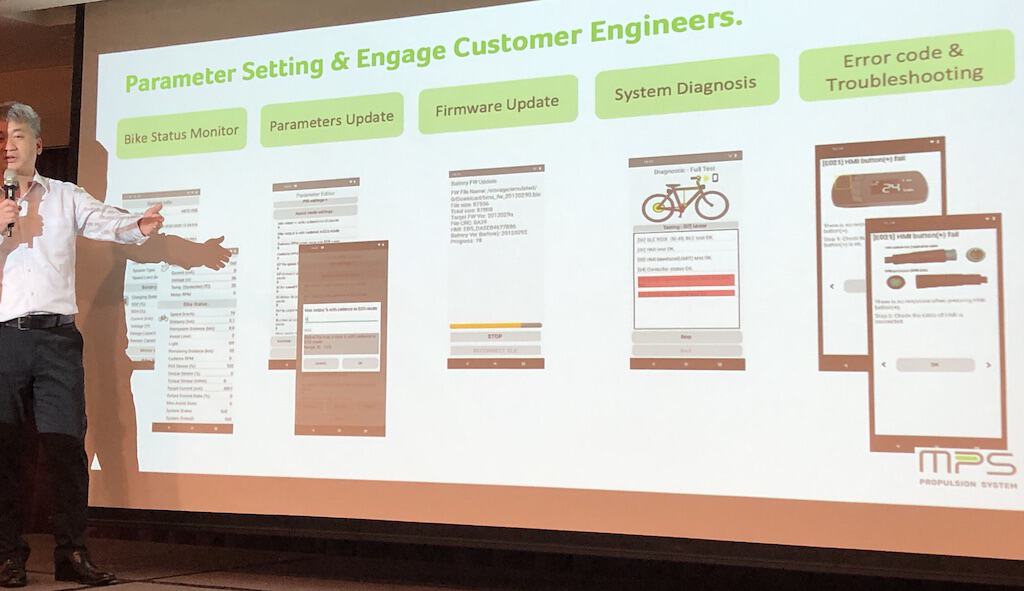

MPS (Acer)

Acer has spawned a number of brands that are now active in e-bike part design and manufacturing.

One is MPS (Mobile Power System Energy Inc) which provides a complete propulsion system, with motor, controller, battery and the often overlooked HMI or Human Machine Interface. (The battery maker, Darfon, is another signficant and growing player in Acer’s stable).

Most bicycle companies that have transitioned to either building complete e-bikes or branched out into e-bike parts and components (and even many startups for that matter) are focused on producing individual parts.

The key to the future—arguably—is probably going to lie with those companies that take a total systems approach, like MPS. Especially in terms of how the user/cyclist interacts with that system. The HMI is at the center of everything in when it comes to the crucial dimension of user experience.

Enlightened companies are generally those that focus on customer experience. And with AI and particularly AIoT systems playing increasingly important roles in e-bike products, the systems approach is likely to dominate.

“AIoT” is a subject that is currently subject to hype and distortion given the rise of AI as recognized integral part of any internet-related technology whether that be B2B or consumer-facing products in 2022.

It’s easy to describe an advanced algorithmic function as “AI” when it’s not—it’s just a very complex nest of “if” “then” statements that take into account changed circumstances BUT are not altered by those changes: there’s no learning to adapt from data input.

In short, critically examine any claims that a system is “intelligent”.

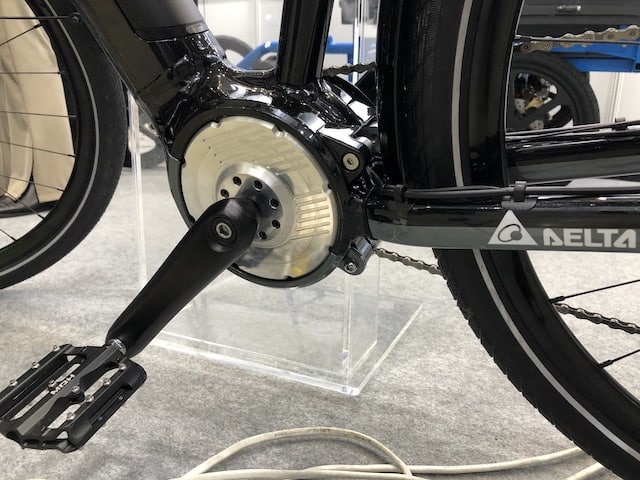

Delta

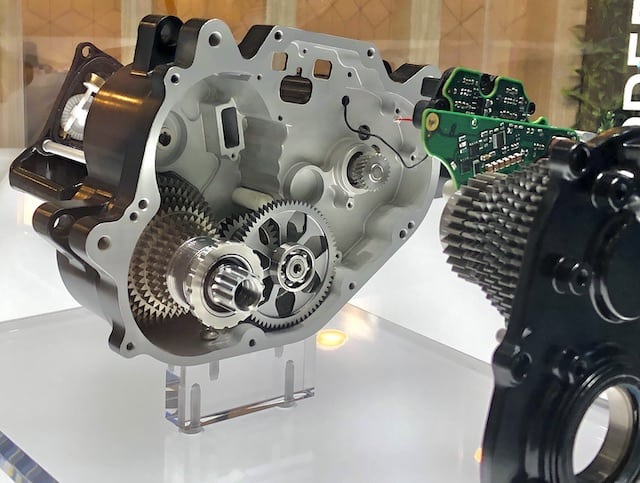

A large, well-established electronics producer who debuted at the 2023 Taipei Cycle with a new motor design that includes a transmission.

No obvious consideration of the HMI dimension here. Still, Delta are poised to become major players except for one obvious area that needs work.

The motor’s presentation is raw.

The trend is for mid-drive motors to be integrated into the bottom bracket and down tube (with the down tube and seat tube increasingly becoming the location of innovative motor systems—see below).

Integration of the motor into the frame has come so far now that it’s increasingly difficult to see the the difference between e-bikes and conventional bikes—not with this one however.

It’s early days for this company, though, so expect to see an expanded range over the next few years.

The depth of technological backing and experience behind MPS and Delta may well mean they take a transformative role e-bike parts and components making over the next decade and become market leaders.

Geared Motors

Valeo bring 100 years experience in designing and manufacturing automotive components to e-bikes.

Precision engineering is allied to attention to the HMI—a “smart system” that monitors a rider’s behavior and adjusts the motor’s electrical assistance to optimize that assistance for the rider.

This is certainly a heavy unit, though. As new entrants into the bicycle industry coming from the automotive industry, you might expect to see a degree of refinement over time. Or perhaps e-cargo is a better fit for this level of product.

On the subject of motors fitting into KH Gears Harmonic drive is designed to deliver a completely smooth drive assistance that is complemented by its integration into the frame—it’s almost indistinguishable from a conventional drive. (General information on the engineering behind harmonic drives).

It basically involved a staggered transmission of power so as to produce a smoother, more stable ride.

That may or may not catch on with the cycling public. By smoothing the transmission of power through the drive train, the stress on chains can be reduced—the surges of power when the motor kicks in requires stronger chains.

Chains

Prior to the rapid uptake of e-bikes and widespread use of mid-drive motors, chains needed to perform well and maintain their strength while getting narrower—10, 11, and then 12 speed means ultra narrow chains.

Chains on non-e-bikes rarely break even under the 1000 watt pressure a pro-rider might exert on a sprint or when pushing hard up a long climb in the Pyrenees.

The wattage that flows through an e-bike drive chain is not necessarily more than a non-electric model especially since most e-bikes are pedal assist—the engine is activated and regulated by pedal cadence.

The difference is the degree of torque exerted on the chain when the motor kicks in which is much higher than the exertion of a pair of legs.

One company specializing in heavy-duty chains for e-bikes and especially cargo bikes is Taya Chain.

Their DHT (Diamond Hard Treatment) increases a chain’s HK (Knoop Hardness) to the extreme value of 2000. These chains last longer on mid-drive systems with up to 160Nm of torque.

The company created a new brand in 2023, Zenas, which is a line of chain specifically for cargo bikes.

The DHT concept of resistance to higher torque over time adapted specifically to cargo bikes with their combination of high torque and heavier loads is likely to be a winner.

Batteries

There are two key trends for batteries that are taking shape:

- ESG and recycling

- Bigger batteries and more of them

The Environmental, Social, and Government policy initiative coming out of the European Union is having as big an impact on e-bike parts and component design and manufacturing as any single issue.

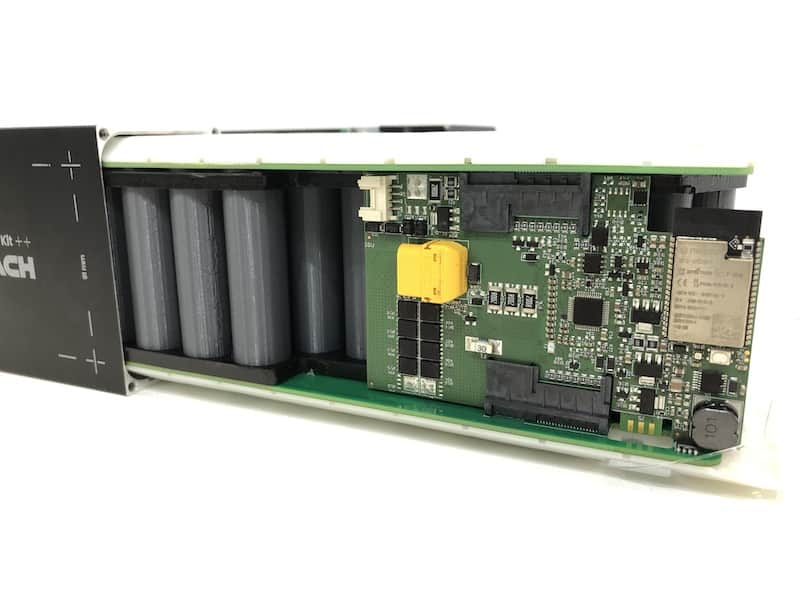

This has spawned perhaps one of the most important innovations in battery design that enables the potential endless recycling of one battery.

The key is to replace the bad cells, since cells are the units that constitute an e-bike battery.

Current manufacturing processes fuse all the cells together making the process of removing defective cells from the structure too expensive.

The Gouach battery is designed to make it easy to identify then remove a defective cell extending the life of a battery way beyond the lifetime of a standard battery.

Bigger batteries are what earned the RouteOhlala a d&i award 3 (longer range e-bikes are a clear trend for obvious reasons).

A design-winning leader in this direction is the “RouteOhlala” touring bike pictured here with the designers at the 2023 Taipei Cycle d&i awards.

The bike is for cyclists who wish to tour the French Alps, particularly those wishing to ride classic Tour de France stages which can take merely mortal riders two days or more to complete.

The twin batteries—one in the down tube and an extra unit in the top tube—extends the daily range to more than 240km.

Custom software regulates the allocation of power from the batteries to the motor. And IoT integration allows monitoring of the system for troubleshooting on the go.

E-bikes with two (or more) large batteries with replaceable cells and the software that controls it which is constantly, seamlessly, updated through cloud connectivity will represent a trend in the remainder of the 2020s.

Cheap Non-Brand Batteries

Battery fires have rapidly increased in recent years with some catastrophic impacts on residents living close to the malfunctioning unit.

The problem seems to be the availability of cheap, non-branded replacement batteries instead of the branded component which is subject to rigorous QC and engineered to work with a particular motor and controller.

Swapping branded parts works for conventional bikes—but when it comes to batteries, using a non-brand replacement is a dicey proposition.

Having said that, we can expect to still see a proliferation of

Controllers

Although an e-bike controller is not the most important e-bike part of them all, there is no part more important.

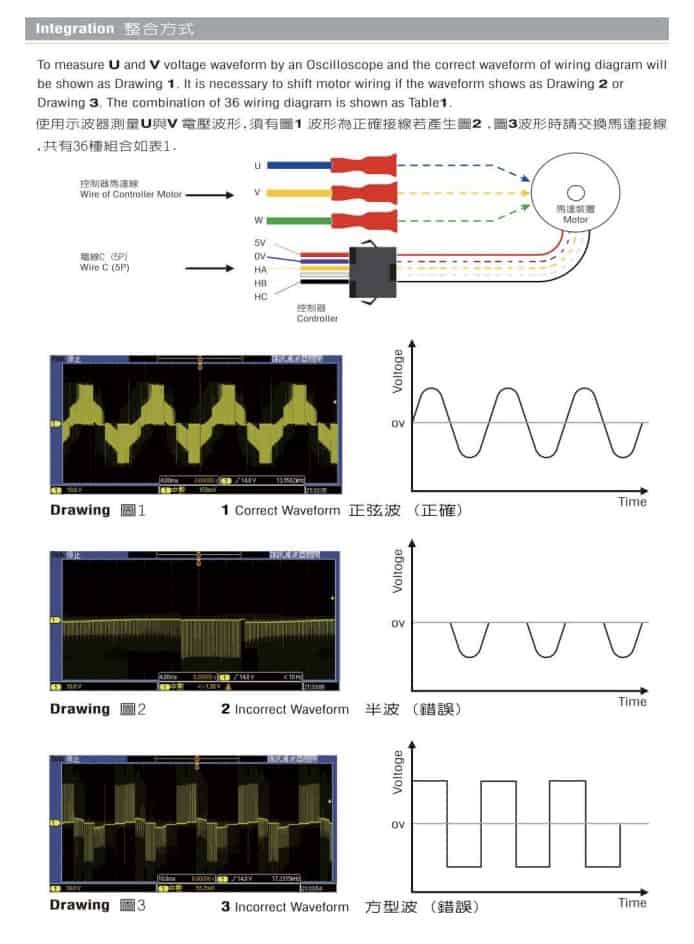

What is a Controller?

It’s a circuit board, often described as an e-bike’s “CPU” that principally regulates the electrical flow from the battery to the motor but also regulates the power flow and functioning of the other electrical components.

And a widespread misconception is that an e-bike makes a bike go faster is incorrect. Advanced controllers may determine the amount of force required to maintain a certain speed up a hill for example.

This is part of the technical specifications for the First Components e-bike controller which we developed many years ago. It’s a complicated bit of kit that requires expertise to develop and troubleshoot. If you’re a brand, you need to choose carefully.

Some controllers are more advanced than others and you can expect the trend towards more advanced controllers as HMI and IoT integrations become exponentially more important in the future. This particularly applies to brushless motors which are lighter and require less maintenance—they also require more advanced controllers.

Other Components

Here’s a glimpse of two categories of e-bike components: one that is possibly just a fad; the other forming a bit of a technical conundrum for the advanced e-bike models on the market. (Possibly a bit ahead of their time).

Removable Seat Posts

A new trend that may well turn out to be a fad is removable seat posts—that once removed can be used as seats—off the bike!

Lights

Lights are the e-bike part that would appear to be perfectly suited to the new environment of e-bikes.

But a problem that came up in the design of the RouteOhlala mentioned earlier shows a mismatch between power output and lights that can handle the power generated.

The twin batteries overload every light they tried which meant the need for an advanced software regulation solution.

There are plenty of innovative bike lights around that, while enhancing the e-bike riding experience, are not specifically “e-bike lights” in that they’d work the same on any bike.

But as that changes, we’ll include coverage of those products here.

Final Thoughts

It’s likely that aside from the odd individual innovation that takes the market by storm, the future belongs to the “whole” not the “parts”.

The parts and components of an e-bike will only have meaning in their combination into powerful systems integrated by IoT connectivity to the cloud or the “edge” as that technology becomes central to EV innovation generally and the need for super low latency interactions between vehicles.

Whatever the future, it’s certainly a fun time to be thinking it through given the rate of technological change.

We’ll continue to monitor changes and build this post out into a chronicle of an exciting time in the bicycle industry.